8 major reasons for LED engineering lights with no light and how to identify quality

Date of release:2018-03-09 Author:Dingfeng Click:

8 reasons why LED engineering lights do not shine

1. The packaging protection of the LED flexible engineering light strip is not perfect, resulting in damage to the lamp bead during the transportation process.

2. The solder joints of the LED flexible engineering lamp strips have a virtual soldering phenomenon, and the vibration during the transportation process causes the solder joints to fall off and the engineering light strips are not bright.

3, LED flexible engineering lamp with less solder, the solder joints are easy to fall off

4, LED flexible engineering lamp with poor solder quality, LED flexible engineering lamp strip during the bending process is prone to brittle fracture, shedding phenomenon

5, LED flexible engineering light strip installation angle is too large, resulting in LED flexible engineering lamp with solder joints separated from the copper foil and lead to no light

6. The LED flexible engineering lamp has excessively extruded the product during installation, resulting in damage to the LED flexible engineering lamp with chip or deformation of the solder joint without falling.

7. LED flexible engineering lamp with circuit board solder mask is too thick, solder and circuit board can not be completely fused together during soldering, it is also a kind of virtual soldering phenomenon.

8. The LED flexible engineering lamp strip can not be twisted during installation. If it is distorted, the solder joint of the LED flexible engineering strip will fall off and cause no light.

How to identify the quality of LED engineering lights:

The LED engineering lights have a mixed market, and the prices of regular manufacturers and cottage products vary greatly. If the quality of LED engineering light strips is identified from the technical point of view, I am afraid that many customers do not have this capability. But we can make a preliminary identification from a simple appearance, and basically can distinguish the quality.

It can be identified mainly from the following aspects:

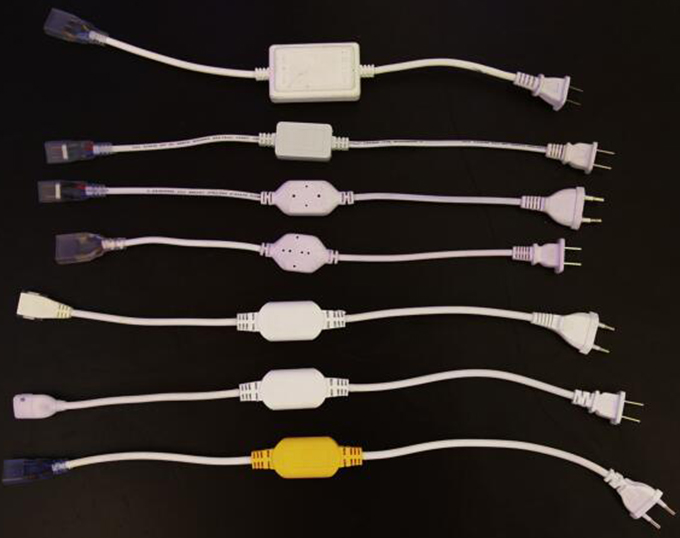

1. The LED engineering lamp strip is produced by SMT patching process using solder paste and reflow soldering. Therefore, the solder joints on the LED engineering lamp strip are relatively smooth and the soldering amount is not much, and the solder joints extend in an arc shape from the FPC pad to the LED electrodes.

2. Look at the quality of FPC. FPC is divided into copper and rolled copper. The copper foil of the copper plate is convex. If you look at it, you can see it from the connection between the pad and the FPC. The rolled copper is closely integrated with the FPC and can be bent freely without peeling off the pad. If the copper plate is bent too much, the pad will fall off. If the temperature is too high during maintenance, the pad will fall off.

3. Look at the cleanliness of the LED engineering light strip surface. If the LED engineering lamp strip produced by the SMT process has a very clean surface, no impurities or stains can be seen. However, if the cottage version of the LED engineering light strip produced by the hand soldering process, the surface will remain stained and cleaned regardless of how it is cleaned.

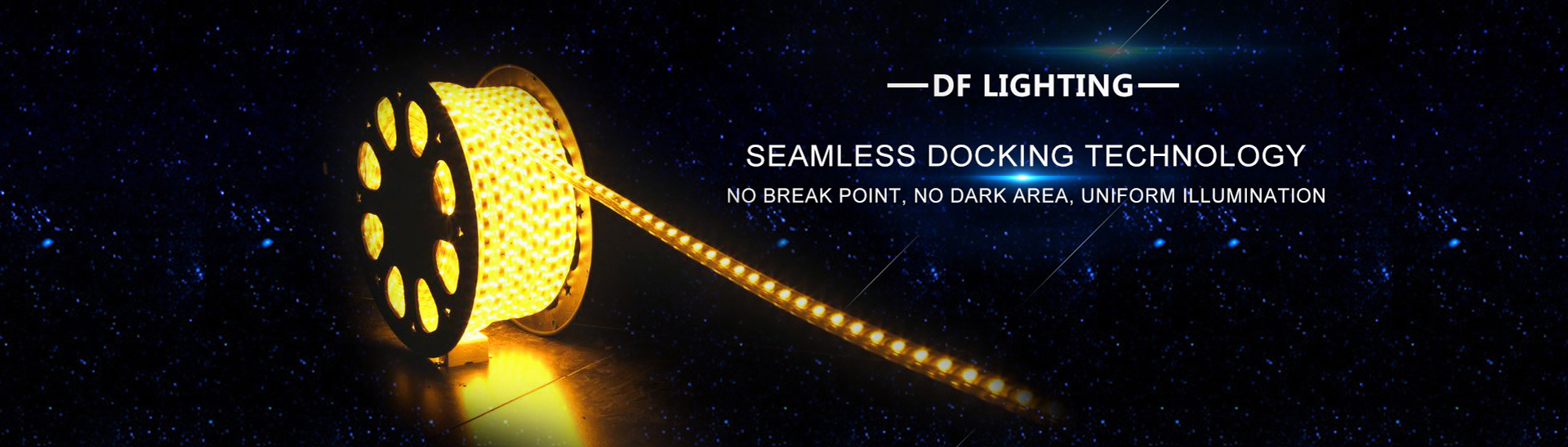

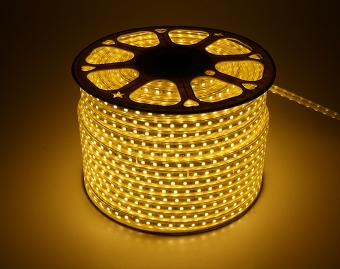

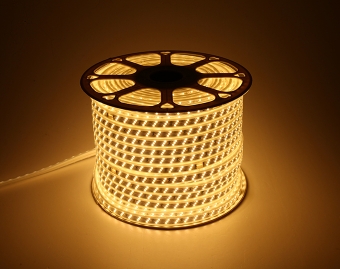

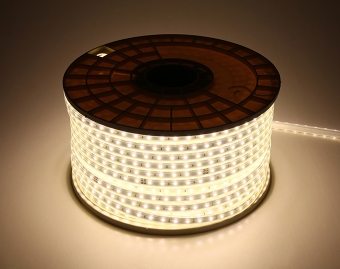

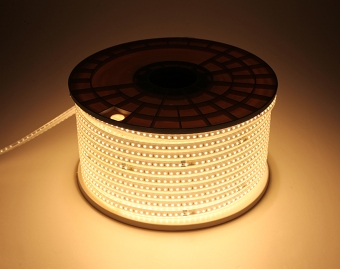

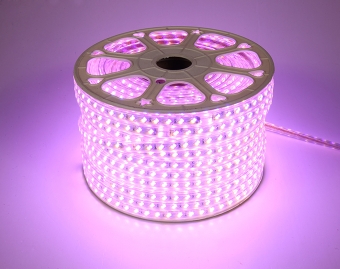

4. Look at the packaging. The regular LED engineering light strips will be packed in anti-static coil trays, usually 5 meters or 10 meters, and then sealed with anti-static moisture-proof bags. The cottage version of the LED engineering light strip will use the recycling coil tray because of cost savings, and then there is no anti-static moisture-proof packaging bag. Look carefully at the coil tray to see the traces and scratches left when the label is removed.

5, look at the label. Regular LED engineering lights with printed labels on the bags and on the reels will have printed labels instead of printed labels.

6, see the attachment. Regular LED engineering light strips will be accompanied by instructions for use and engineering light strips in the box, and will also be equipped with LED engineering lights with connectors or card holders; while the cottage version of LED engineering lights is not in the box. These accessories, because some manufacturers can still save the province after all.

The address of this article:http://en.dfled.net/news/367.html

Key word:

The next one:Summarize some LED engineering light belt knowledge

Recently browse:

Related products:

Related news:

- Briefing on the relevant maintenance instructions for outdoor engineering light strips

- LED engineering lights with the "besiering" competition in the brand price market

- Hotel lights with starting point are more comfortable with warm white

- LED hotel light strip is proportional to price and quality

- Summarize some LED engineering light belt knowledge

- What are the reasons for the price difference of LED hotel lights

- How to solve the problem that LED hotel lights have a bad light effect

- Affordable engineering light strips are available in a wide range of prices

- Talking about the Factors Affecting the Life of Export Lamp Strips

- Why design engineering light strips Do you know the advantages