Briefing on the relevant maintenance instructions for outdoor engineering light strips

Date of release:2018-10-26 Author:Dingfeng Click:

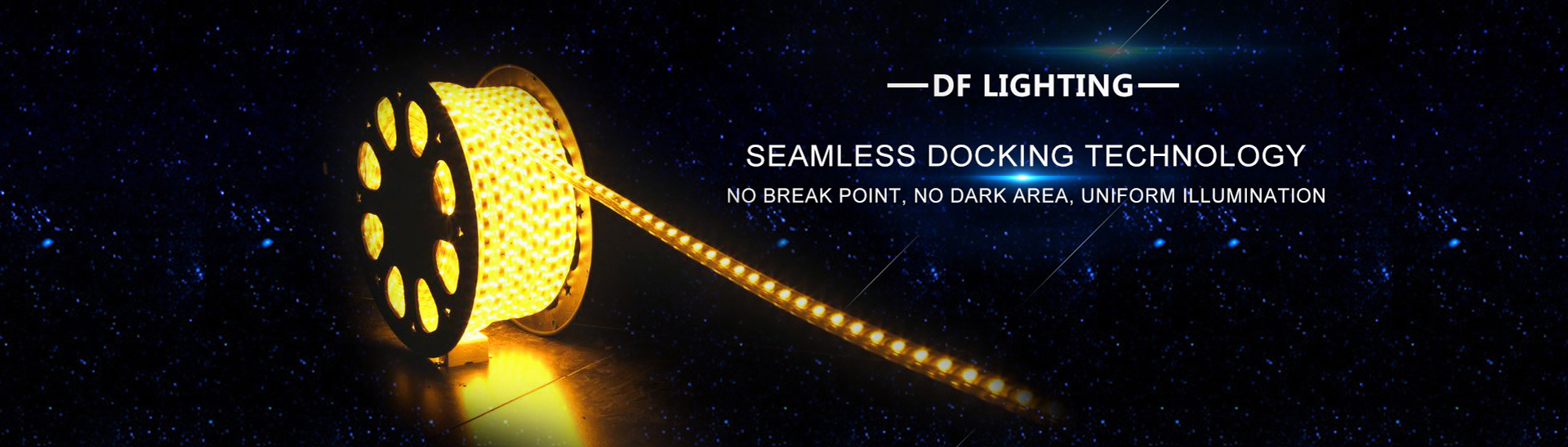

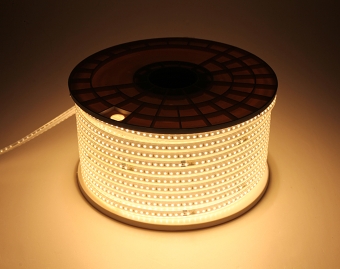

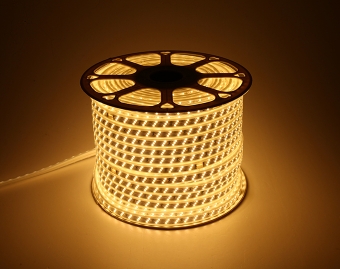

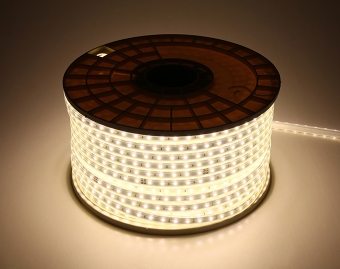

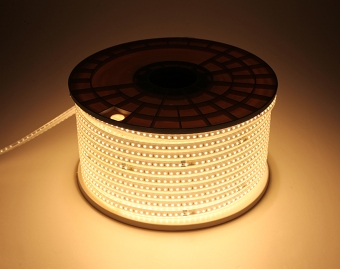

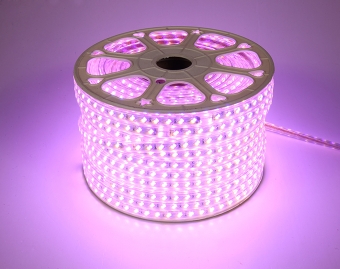

The engineering lamp strip refers to the LED lamp is soldered on the copper wire or the strip flexible circuit board with a special processing technology, and then connected to the power source to emit light, which is named because of the shape of a light strip when it emits light.

Engineering light strips have been widely used in buildings, bridges, roads, gardens, courtyards, floors, ceilings, furniture, cars, ponds, underwater, advertising, signage, signs, etc., for decoration or lighting, for various festivals For example, Christmas, Halloween, Valentine's Day, Easter, National Day, etc. have added endless joy and festive atmosphere. It has entered the five dominant markets of advertising, decoration, architecture, commercial and gift with tenacious vitality.

The engineering lamp belt adopts ultra-high brightness SMD as the light source, combined with the production method of ordinary engineering lamp belt, which is made of SMD lamp strip. In addition to the characteristics of small size and high brightness, it also has the characteristics of long length and convenient installation. Ordinary SMD lamps have a wider range of uses, reliability, safety, and advantages in high-voltage products.

The two main groups of engineering light strips are made into adult LEDs and FPCs, all of which have no cargo that can withstand low temperatures. If the FPC is continuing to cool down or exceeds its acceptance, it will crack the FPC cover film and indirectly form the engineering lamp strip. At the same time, the LED has not been able to withstand the low temperature, and it is going to be cold for a long time, and its chip will be burned at a low temperature. Therefore, the electric soldering iron adopted in the training of the lamp strip must adopt the temperature-controlled electric soldering iron, and the measurement limit is in the first category, and the random change and setting can be stopped. In addition, even so, it is also necessary to pay attention to the electric iron in the training. It is not necessary to stop the LED pin for more than 10 seconds. If it exceeds a certain time, it will burn out the LED chip.

Many engineering lights are not bright because there is a short circuit at the foot. Before training, it is necessary to investigate the real lack of light. Otherwise, after rushing to change the LED that is not bright, the chip that continues to form the LED will be broken by the short-circuit direct current when it is returned again. Because, in the process of changing the new LED in advance, we must first find the real reason for not bright, and some of the ability to do things.

The address of this article:http://en.dfled.net/news/399.html

Key word:工程灯带,酒店灯带,出口灯带

The next one:None