Talking about the Factors Affecting the Life of Export Lamp Strips

Date of release:2018-03-19 Author:Dingfeng Click:

In general, the factors that limit the life of the exit lamp:

LEDs are static-sensitive components. If you do not take anti-static measures when repairing the exit lamp strip, it will burn out the LED and cause waste. Of course, the life of the exit light strip is not guaranteed. Poor toughness of the copper wire or flexible circuit board of the exit lamp strip can cause the exit lamp strip to break during bending and also affect the life of the exit strip.

The power supply factor, the exit light strip is generally powered by a constant voltage power supply (DC switching power supply). If the output of the power supply is unstable or there is no surge protection, it will output unstable voltage and current when the external network voltage fluctuates. Leading the outlet strip to work at non-standard voltages will also affect its useful life. Since the LEDs are constant current components, the constant lamp effects of the outlet lamps produced by different manufacturers are different, and the life expectancy is different.

In addition to the most common poor heat dissipation, LED dead light or light decay according to the application experience, the cause of discoloration is also caused by the pollution of chemical substances in the manufacturing process, for the downstream application side, in addition to the proper heat dissipation solution In addition, in the process of assembly of the luminaire, or the chemical additives of the manufacturing process, it is necessary to avoid the so-called chemical incompatibility.

Incompatible VOCs in LED lighting can quickly damage any manufacturer's LEDs. This chemical incompatibility is often a local phenomenon occurring at elevated temperatures and in sealed lamps with little or no air flow. After testing by the LED packaging factory, it is found that some chemicals that are known to easily affect the normal function of the LED, the user end is best to establish a comprehensive chemical incompatibility test evaluation system. With proper precautions, design and testing, the impact can be minimized or eliminated.

Line design problem

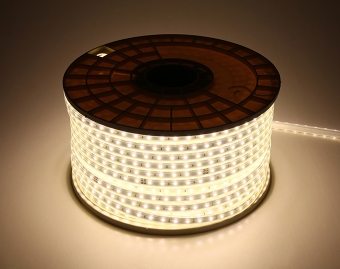

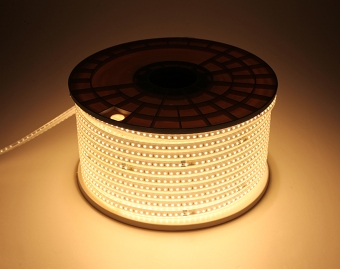

The most commonly used specifications for the exit lamp strip are 12V and 24V. The 12V is a 3-string multi-channel parallel structure, and the 24V is a 6-string multi-channel parallel structure. Since the exit light strips are to be connected, each light strip is specific. How long can be connected, and the width of the line and the thickness of the copper foil have a great relationship with the design. Because the current intensity per unit area can be related to the cross-sectional area of the line, if this is not taken into account when wiring, the light bar will be over-current when the connection length exceeds the current that the line can withstand. The heat, while damaging the circuit board, also reduces the service life of the LED.

Production process problem

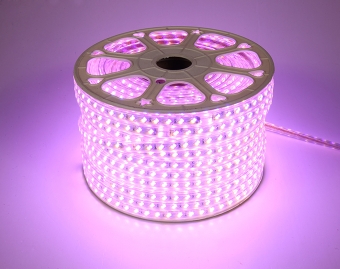

Since the outlet strips are series-parallel, when a short circuit occurs in a certain group of loops, the other LED voltages of the same group will rise, the brightness of the LED will increase, and the corresponding heat will increase. . The most obvious is that in the 5050 light bar, when the 5050 light bar is short-circuited in any one of the chip circuits, the current of the one that causes the short circuit doubles, that is, 20mA becomes 40mA, and the brightness of the lamp bead It will become very bright, but at the same time the amount of heat will increase dramatically, and the board will burn out in a matter of minutes. However, this problem is relatively concealed, and generally it is not very noticeable, because the short circuit does not affect the normal illumination of the light bar. If the employee in charge of the test only pays attention to whether the LED is illuminated, not to check the brightness abnormality, or not to do it. Appearance inspection, only for electrical measurements, will often ignore this problem, which is why many export lamp manufacturers always encounter customer complaints that the product is hot but can not find the reason.